【编辑推荐】2024年2期技术交流、讨论会

技术交流

张建1,张晔1,徐熙林1,李青春1,李爱魁2∗

(1. 辽宁电力交易中心有限公司,辽宁 沈阳 110006;2. 大连理工大学电气工程学院,辽宁 大连 116024)

摘要:为提高全钒液流电池电堆充放电电流密度,开发大功率电堆,首先将电极与双极板热熔焊接成复合极板,然后将复合极板与液流框激光焊接成整体化组件,组装成整体化液流电池电堆,简化了人工组组装步骤,降低了组装人工量,提高了组装能力。与传统电堆相比,整体化液流电池电堆欧姆内阻由20.2 mΩ降为12.1 mΩ,这主要是由于整体化液流电池电堆采用焊接方式,降低了电极与双极板的接触内阻。在不同电流密度、不同流速下对整体化电堆进行充放电测试,测试结果表明,在125 mA/cm2电流密度下,整体化液流电池电堆电压效率为82.8%,相比传统电堆电压效率(80.3%)高2.5个百分点,当充放电电流密度为200 mA/cm2,整体化液流电池电堆能量效率仍大于75%。通过优化运行条件,进一步提高了电堆性能,当电解液流速超过0.95 m3/h时,电堆能量效率基本不再变化,但放电容量会进一步提高,即电解液利用率进一步提高;当放电截止电压由10.0 V优化为10.5 V时,在200 mA/cm2的充放电电流密度下,整体电堆电压效率由78.4%提高到80.0%,同时,电解液利用率基本无变化。经过200次不间断的循环,整体化电堆能量效率由76.5%降低到73.3%,降低了3.2个百分点,电压效率由80.6%降低到77.4%,降低了3.1个百分点,主要是由于双极板与电极的焊接有所脱落,说明整体化电堆在强酸、强氧化性中的焊接稳定性还有待提高,还需要进一步研究焊接工艺的改进,以提高整体化电堆的稳定性。

Development of integrated all-vanadium redox-flow battery stack

ZHANG Jian1, ZHANG Ye1, XU Xilin1, LI Qingchun1, LI Aikui2∗

(1. Laoning Power Exchange Center Co., Ltd., Shenyang, Liaoning 110006, China; 2. School of Electrical Engineering, Dalian University of Technology, Dalian, Liaoning 116024, China)

Abstract:In order to improve the charge and discharge current density of all-vanadium redox flow battery stack and develop a high-power stack, the electrode and bipolar plate are hot-melt welded to form a composite plate, and then the composite plate and liquid flow frame are laser welded into a monolithic component, and assembled into an integrated redox flow battery stack. This simplifies the assembly steps of the artificial group, reduces the assembly labor, and improves the assembly capacity. Compared with the traditional stack, the Ohmic internal resistance of the integrated flow battery stack is reduced from 20. 2 mΩ to 12.1 mΩ. This is mainly due to the welding method of the integrated flow battery stack, which reduces the contact internal resistance between the electrode and the bipolar plate. The integrated flow battery stack is charged and discharged under different current densities and flow velocities. The voltage efficiency of the integrated flow battery stack is 82. 8% at a current density of 125 mA/cm2, which is 2.5 percentage points higher than that of the traditional stack. When the current density is 200 mA/cm2, the energy efficiency of the integrated flow battery stack is still greater than 75%. By optimizing the operation conditions, the performance of the integrated flow battery stack is further improved. When the electrolyte flow rate exceeds 0. 95 m3 / h, the energy efficiency of the stack basically does not change, but the discharge capacity, that is, the electrolyte utilization rate, will be further improved. When the discharge cut-off voltage is optimized from 10.0 V to 10.5 V, the voltage efficiency of the integrated stack is increased from 78.4% to 80. 0% at a current density of 200 mA/cm2, the electrolyte utilization rate is basically unchanged. After 200 continuous cycles, the energy efficiency of the flow battery stack has decreased from 76.5% to 73.3%, which is 3.2 percentage points lower than the initiatory integrated stack, and the voltage efficiency has decreased from 80.6% to 77.4%, which is 3.1 percentage points lower than the initiatory integrated stack, mainly due to the welding off of the bipolar plate and the electrode. The welding stability of the integrated redox flow battery stack in strong acid and strong oxidation still needs to be improved, and further research is needed to improve the welding technology to improve the stability of the integrated stack.

引用格式

张建,张晔,徐熙林,等. 整体化全钒氧化还原液流电池电堆的开发[J]. 电池,2024,54(2):200-204.

ZHANG J,ZHANG Y,XU X L,et al. Development of integrated all-vanadium redox-flow battery stack[J].Dianchi(Battery Bimonthly) 2024,54(2):200-204.(点此下载文章全文)

李亨利1,2∗,徐荣益2,王昭沛1,李意能1

(1. 曲靖市德方纳米科技有限公司,云南 曲靖 655000;2. 佛山市德方纳米科技有限公司,广东 佛山 528500)

摘要: 磷酸锰锂(LiMnPO4)材料的电导率低且充放电过程易发生Jahn-Teller效应,导致电化学性能稍差。通过液相法将原材料的各元素以原子级均匀混合,结合固相法焙烧工艺降低制备成本,合成磷酸锰铁锂(LiMn0.6Fe0.4PO4)正极材料,并对晶体结构、放电曲线特性、循环性能等进行分析。Fe均匀地掺入Mn位形成固溶体,样品的电化学性能得到改善。在2.0~4.3 V下,0.1 C倍率的放电比容量为156.5 mAh/g;常温下以1.0 C倍率循环2 000次,容量保持率超过80%。循环前、后的正极活性物质的晶体结构及颗粒剖面形貌对比,循环性能衰减主要源于循环过程中正极材料颗粒产生裂纹及颗粒粉化。

Performance of LiMn0.6Fe0.4PO4 synthesized via liquid-solid phase method

LI Hengli1,2∗, XU Rongyi2, WANG Zhaopei1, LI Yineng1

(1. Qujing Dynanonic Co.,Ltd., Qujing, Yunnan 655000, China; 2. Foshan Dynanonic Co., Ltd., Foshan, Guangdong 528500, China)

Abstract: The poor electrochemical performance of manganese lithium phosphate(LiMnPO4) is caused by its low conductivity and Jahn-Teller effect during the charge-discharge process. Manganese iron lithium phosphate (LiMn0.6Fe0.4PO4) cathode material is synthesized by uniformly mixing the various elements of the raw materials at the atomic level through the liquid-phase method, combined with solid-state calcination process to reduce preparation costs. Its crystal structure, discharge curve, and cycle performance are analyzed. The Fe is doped into the Mn site to form a solid solution, and the electrochemical performance of the sample is improved. At 2.0-4.3 V, the 0.1 C rate-specific discharge capacity is 156.5 mAh/g, and the capacity retention rate is above 80% during 2 000 cycles at 1.0 C rate at room temperature. The comparison of the crystal structure and particle profile morphology of the cathode active material before and after cycling shows that the capacity fade is mainly due to crack formation and particle pulverization during the cycle process.

引用格式

李亨利,徐荣益,王昭沛,等. 液-固相法合成LiMn0.6Fe0.4PO4的性能[J]. 电池,2024,54(2):205-208.

LI H L,XU R Y,WANG Z P,et al. Performance of LiMn0.6Fe0.4PO4 synthesized via liquid-solid phase method[J] .Dianchi(Battery Bimonthly),2024,54(2):205-208.(点此下载文章全文)

滕久康,吴宁宁,王 畅,陈晓涛∗

(贵州梅岭电源有限公司,特种化学电源全国重点实验室,贵州 遵义 563003)

摘要:硬碳作为钠离子电池负极材料具有成本低、容量高和循环性能好等优势,黏结剂种类的选取对硬碳材料性能有很大的影响。选用油系聚偏氟乙烯(PVDF)黏结剂和水系海藻酸钠(SA)、聚丙烯酸钠(PPANa)和水系羧甲基纤维素(CMC)黏结剂,研究黏结剂种类对硬碳材料性能的影响。相比于油系黏结剂,水系黏结剂更适用于硬碳材料,SEM和极片电阻率结果显示,水系黏结剂的分散效果更好,制备的电池电阻率更低。电化学测试结果表明,水系黏结剂制备的电池电化学性能更优,首次库仑效率(ICE)值均高于87%,而油性黏结剂PVDF制备的电池ICE值仅有70.5%。SA和PAANa两种水系黏结剂制备的电池在1.0 C下循环100次,可逆容量稳定在320 mAh/g左右,而CMC和PVDF制备的电池分别仅为270 mAh/g、260 mAh/g,且SA和PAANa制备的电池电化学阻抗最低。但水系黏结剂的最佳添加比还需进一步探究,提升硬碳材料性能,以期实现硬碳材料最优化。

Effect of binders on the performance of hard carbon anode material

TENG Jiukang, WU Ningning, WANG Chang, CHEN Xiaotao∗

(Guizhou Meiling Power Sources Co., Ltd, State Key Laboratory of Advanced Chemical Power Sources, Zunyi, Guizhou 563003, China)

Abstract:Hard carbon as anode material for sodium-ion batteries has advantages such as low cost, high capacity, and good cycling performance. The selection of different types of binders has a significant impact on the performance of hard carbon. Oil-based polyvinylidene fluoride (PVDF) binder and water-based sodium alginate (SA), sodium polyacrylate (PPANa), and water-based carboxymethyl cellulose (CMC) binder are selected to study the effect of binder types on the properties of hard carbon materials. Compared to oil-based PVDF, water-based binders are more suitable for hard carbon. SEM and electrode resistivity results show that water-based binders have a better dispersion effect and lower resistivity. The electrochemical test results show that the electrochemical performance of the batteries prepared with water-based binder is better, with the initial Coulombic efficiency (ICE) values higher than 87%, while the ICE value of the batteries prepared with oil-based binder PVDF is only 70.5%. The batteries prepared with SA and PAANa water-based binders have a reversible capacity stable at around 320 mAh/g after 100 cycles at 1.0 C, while the batteries prepared with CMC and PVDF only have 270 mAh/g and 260 mAh/g, respectively. The electrochemical impedance of the batteries prepared with SA and PAANa is the lowest. However, the optimal addition ratio of aqueous binders needs to be further explored to improve the performance of hard carbon materials and to achieve the optimization of hard carbon materials.

图1 以SA、PAANa、PVDF和CMC为黏结剂制备电池的倍率性能图

Fig.1 Rate capability of batteries using SA, PAANa, PVDF and CMC as binder

引用格式

滕久康,吴宁宁,王畅,等. 黏结剂对硬碳负极材料性能的影响[J]. 电池,2024,54(2):209-212.

TENG J K,WU N N,WANG C,et al. Effect of binders on the performance of hard carbon anode material[J] . Dianchi(Battery Bimonthly),2024,54(2):209-212.(点此下载文章全文)

刘中奎∗,陈峰

(合肥国轩电池有限公司,安徽 合肥 230001)

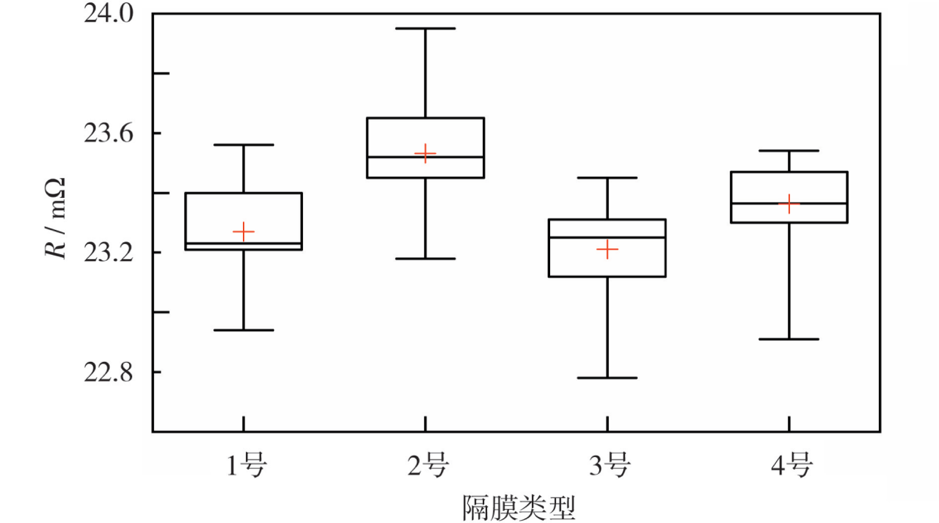

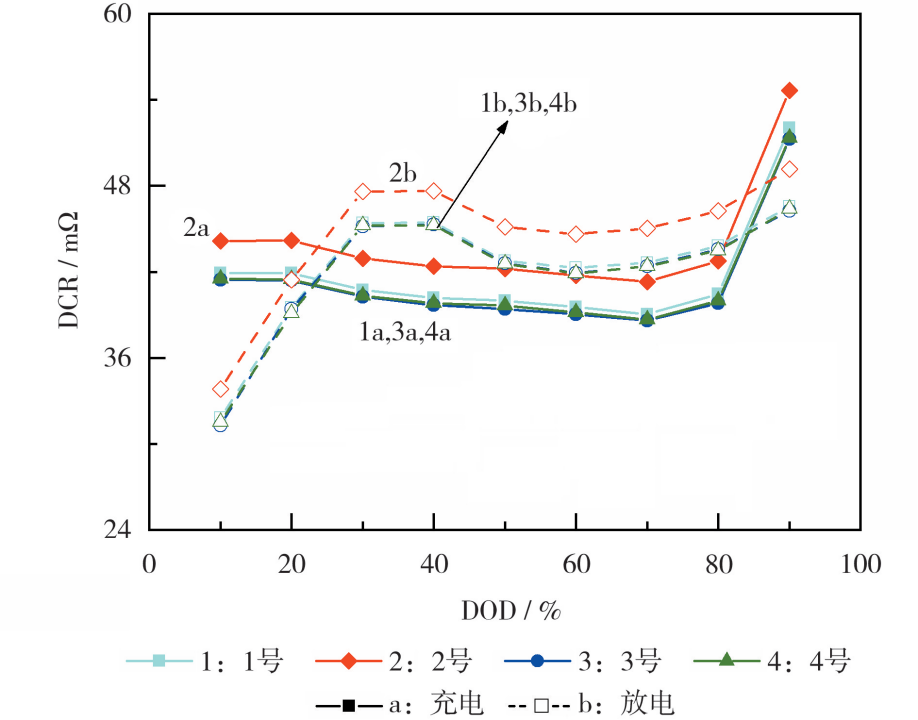

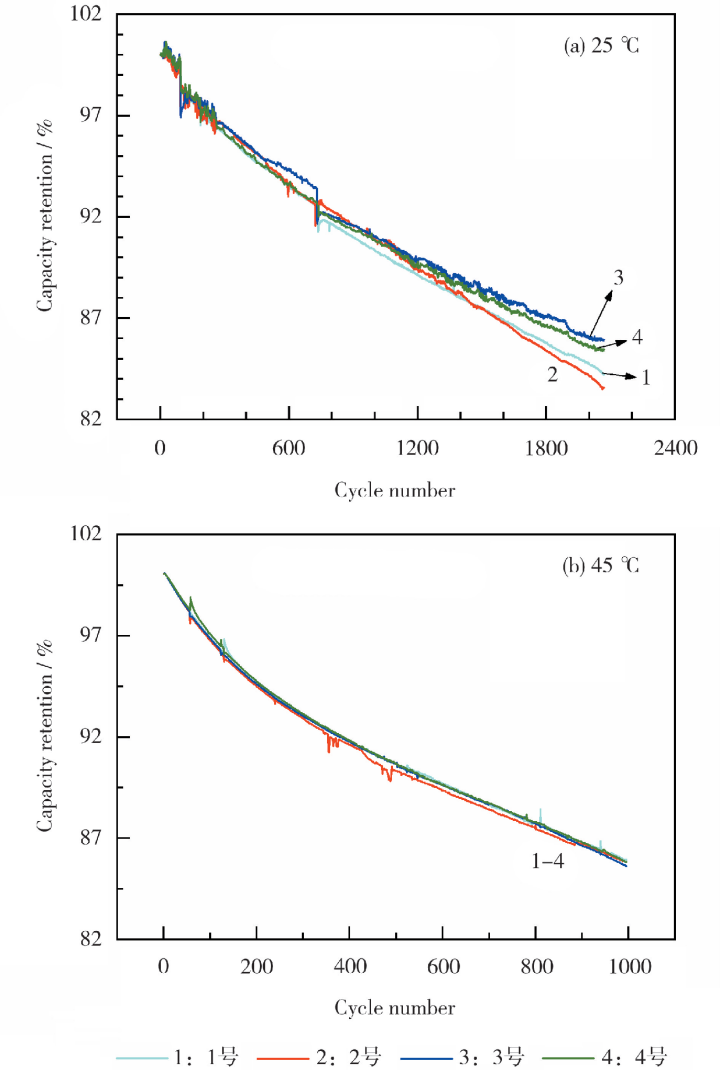

摘要:以3 Ah软包装动力锂离子电池作为研究对象,考察喷涂和辊涂两种不同类型水系涂胶隔膜对电池性能的影响。1号为双面辊涂0.5 g/m2水系PVDF胶隔膜、2号为双面辊涂0.9 g/m2水系PVDF胶隔膜、3号为双面喷涂0.5 g/m2水系PVDF胶隔膜,4号为双面喷涂0.9 g/m2水系PVDF胶隔膜。相同涂胶面密度的隔膜,3号和4号均比1号和2号的厚度略大1 μm以上,透气度降低约20 s,与正负极片间的黏结力略低0.5 N/ m,喷涂相比辊涂涂胶层对隔膜透气度的影响较小,涂层覆盖率稍低,影响了与极片间的黏结力。实验制备的3 Ah软包装锂离子电池性能存在差异,与1号和2号电池相比,3号和4号电池具有较低的分容内阻和脉冲充放电DCR。以不低于2.00 C充放电,倍率充电恒流充入比高约1%,倍率放电容量比高约0.2%,-20 ℃放电容量与25 ℃的容量比低约3%以上,相同涂覆工艺下,喷涂涂胶隔膜涂胶量面密度的增加对电池内阻的影响较小,可能与喷涂涂胶层覆盖率低,对隔膜孔径和透气度值影响较小,对离子传输性能影响较小有关。25 ℃和45 ℃下循环1 000次,两种涂胶隔膜电池性能差异较小。25 ℃下循环超过1 000次后,3号和4号电池的循环性能与1号和2号电池相比稍好,循环至2 000次的容量保持率高约1.7%,喷涂涂胶隔膜相比辊涂涂胶更有利于电池长期的循环寿命,可能和喷涂涂胶层对隔膜的离子传输通道影响较小相关。

Effect of adhesive-coated separator on performance of Li-ion battery

LIU Zhongkui∗, CHEN Feng

(Hefei Gotion Battery Co., Ltd., Hefei, Anhui 230001, China)

Abstract: A 3 Ah flexible packaging power Li-ion battery is used as the research object to investigate the effects of spraying and roller coating on the performance of the battery. No.1 is a double-sided roller coated with 0.5 g/m2 water PVDF glue separator, No.2 is a double-sided roller coated with 0.9 g/m2 water PVDF glue separator, No.3 is a double-sided spray with 0.5 g/m2 water PVDF glue separator, and No.4 is a double-sided spray with 0.9 g/m2 water PVDF glue separator. For the separator with the same adhesive surface density, the thickness of No.3 and No.4 is slightly larger than that of No.1 and No.2, the permeability is reduced by about 20 s, and the adhesion between the cathode and anode sheets is slightly lower than 0.5 N/m. Compared with the spray, the roller coating has less influence on the permeability of the separator, and the coating coverage is slightly lower, which affects the adhesion between the pole sheets. The performance of the 3 Ah flexible packaging Li-ion batteries prepared is different. Compared with the No.1 and No.2 batteries, No.3 and No.4 batteries have lower partition-capacitance internal resistance and pulse charge-discharge DCR. Charge and discharge at no less than 2.00 C, rate charge constant current charging ratio is about 1% higher, rate discharge capacity ratio is about 0.2% higher, discharge capacity ratio of -20 ℃ is about 3% lower than that of 25 ℃, under the same coating process, the increase in the coating surface density of spray coating separator has little influence on the internal resistance of the battery, which may be related to the low coverage rate of spray coating layer. It has little influence on the membrane pore size and permeability value and has little influence on ion transport performance. After 1 000 cycles at 25 ℃ and 45 ℃, the performance difference between the two coated separator batteries is small. After cycling more than 1 000 times at 25 ℃, the cycle performance of No.3 and No.4 batteries is slightly better than that of No.1 and No.2 batteries, and the capacity retention rate of cycling to 2 000 times is about 1.7% higher. Compared with roll coating, spray coating separator is more conducive to the long-term cycle life of batteries. It may be related to the small effect of spraying the adhesive layer on ion transport channel of the separator.

图1 不同隔膜制备电池分容后的内阻

Fig.1 Internal resistance of batteries prepared with different separators after capacity grading

图2 不同隔膜制备电池的脉冲性能

Fig.2 Pulse performance of batteries with different separators

图3 不同隔膜制备电池的循环性能

Fig.3 Cycle performance of batteries with different separators

引用格式

刘中奎,陈峰. 涂胶隔膜对锂离子电池性能的影响[J]. 电池,2024,54(2):213-216.

LIU Z K,CHEN F. Effect of adhesive-coated separator on performance of Li-ion battery[J]. Dianchi(Battery Bimonthly),2024,54(2):213-216.(点此下载文章全文)

郑玲玲1,智茂永1,2∗,岳 姗1,潘治衡1

(1. 中国民用航空飞行学院民航安全工程学院,四川 德阳 618307;2. 民机火灾科学与安全工程四川省重点实验室,四川 德阳 618307)

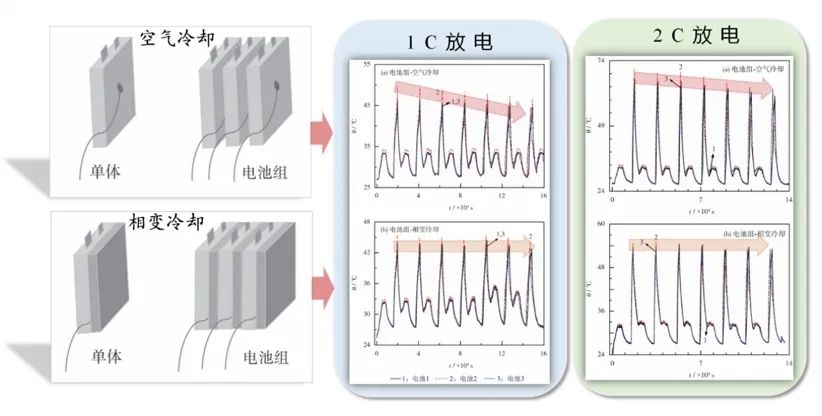

摘要:锂离子电池的工作性能对温度非常敏感,温度过高或过低都会损坏其使用寿命。高倍率放电时,电池内部反应剧烈并产生大量热量,温度骤升,甚至会有热失控的风险,过低的温度会使其容量骤减,需要热管理系统对其进行温度调控,保证电池在安全温度范围内运行。相比较于传统的冷却方式,相变冷却具有成本低、温度均匀性好、无外接电源等优势,具有重要的研究价值和应用前景。为了控制锂离子电池的最高温度及温度均匀性,制备了高热导率和优异稳定性的水合盐相变复合材料,并用于电池热管理性能的实验研究。结果表明,当添加5%(质量分数)的膨胀石墨时,复合材料的相变温度和相变热焓分别是45.31 ℃和196.17 J/g,热导率为1.60 W/(m·K),并具有优异的抗泄露能力;在室温环境(25 ℃)下,当放电倍率为2 C时,相变冷却的单体电池的最大温差为0.21 ℃,比空气冷却降低了89.55%;相变冷却可以将电池组的最高温度控制在55 ℃以内,比空气冷却降低了22.24%,电池组间的最大温差为2.41 ℃,比空气冷却降低了77.46%。与空气冷却相比,锂离子电池在高倍率下放电时,相变冷却可以明显提高电池组的温度均匀性,并使其处于合适的温度范围。实验为相变材料在电池热管理中的应用研究提供参考,促进相变材料在电池热管理中的研究及应用。

Hydrated salt phase change composite used in thermal management of Li-ion battery

ZHENG Lingling1,ZHI Maoyong1,2*,YUE Shan1,PAN Zhiheng1

(1. College of Civil Aviation Safety Engineering, Civil Aviation Flight University of China, Deyang, Sichuan 618307, China; 2. Civil Aircraft Fire Science and Safety Engineering Key Laboratory of Sichuan Province, Deyang, Sichuan 618307, China)

Abstract: The working performance of Li-ion batteries is very sensitive to temperature, and too high or too low temperatures can damage their service life. When discharging at high rates, the internal reaction of the battery is violent and a large amount of heat is generated, causing a sudden increase in temperature and even a risk of thermal runaway. A low temperature causes a sudden decrease in its capacity, and a thermal management system is needed to regulate its temperature to ensure that the battery operates within a safe temperature range. Compared to traditional cooling methods, phase change cooling has advantages such as low cost, good temperature uniformity, and no external power supply, and has important research value and application prospects. To control the maximum temperature and temperature uniformity of Li-ion batteries, hydrated salt phase change composite material with high thermal conductivity and excellent stability is prepared, and its thermal management performance of Li-ion batteries is investigated. The results indicated that when adding 5% (mass fraction) expanding graphite, the phase change temperature and enthalpy of the composite material are 45.31 ℃ and 196.17 J/g, respectively, with a thermal conductivity of 1.60 W/(m·K) and excellent anti-leakage ability. At room temperature (25 ℃), when the discharge rate is 2 C, the maximum temperature difference of phase change-cooled single-cell battery is 0.21 ℃, which is 89.55% lower than that of air cooling. Phase change cooling could control the maximum temperature of battery packs within 55 ℃, which is 22.24% lower than air cooling. The maximum temperature difference between battery packs is 2.41 ℃, which is 77.46% lower than air cooling. Compared with air cooling, phase change cooling could significantly improve the temperature uniformity of batteries at high discharge rates and keep them in an appropriate temperature range. The experiment provides references for phase change materials and their applications in battery thermal management, promoting the research and application of phase change materials in battery thermal management.

图1 电池热管理测试示意图和电池组表面温度

Fig.1 Diagram of battery thermal management testing and surface temperatures of battery pack

引用格式

郑玲玲,智茂永,岳姗,等. 水合盐相变材料用于锂离子电池热管理[J]. 电池,2024,54(2):217-221.

ZHENG L L,ZHI M Y,YUE S,et al. Hydrated salt phase change composite used in thermal management of Li-ion battery[J]. Dianchi(Battery Bimonthly),2024,54(2):217-221.(点此下载文章全文)

袁天明∗,孙晓辉,阮 超,李景康

(杭州南都动力科技有限公司工艺技术部,浙江 杭州 311103)

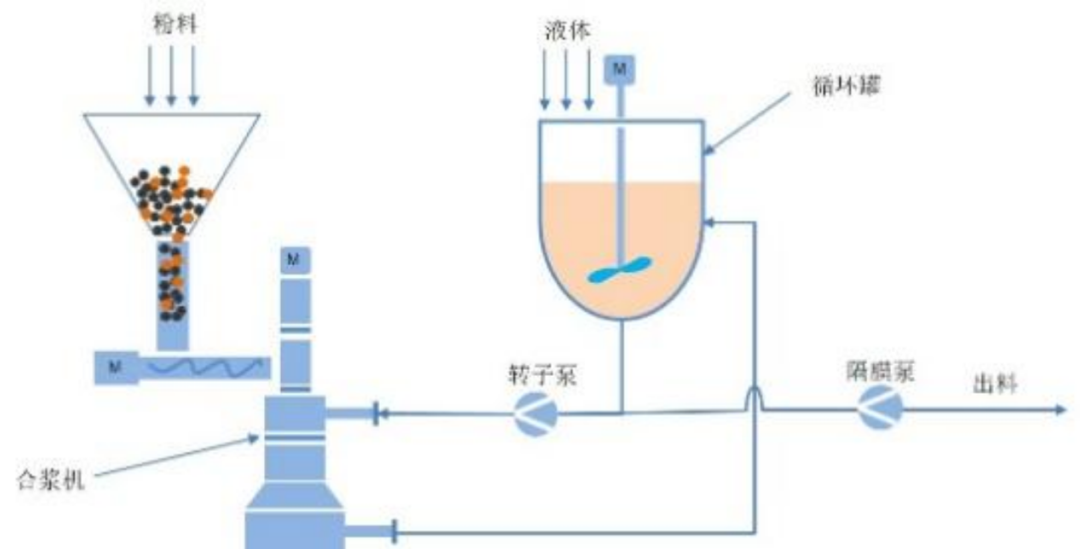

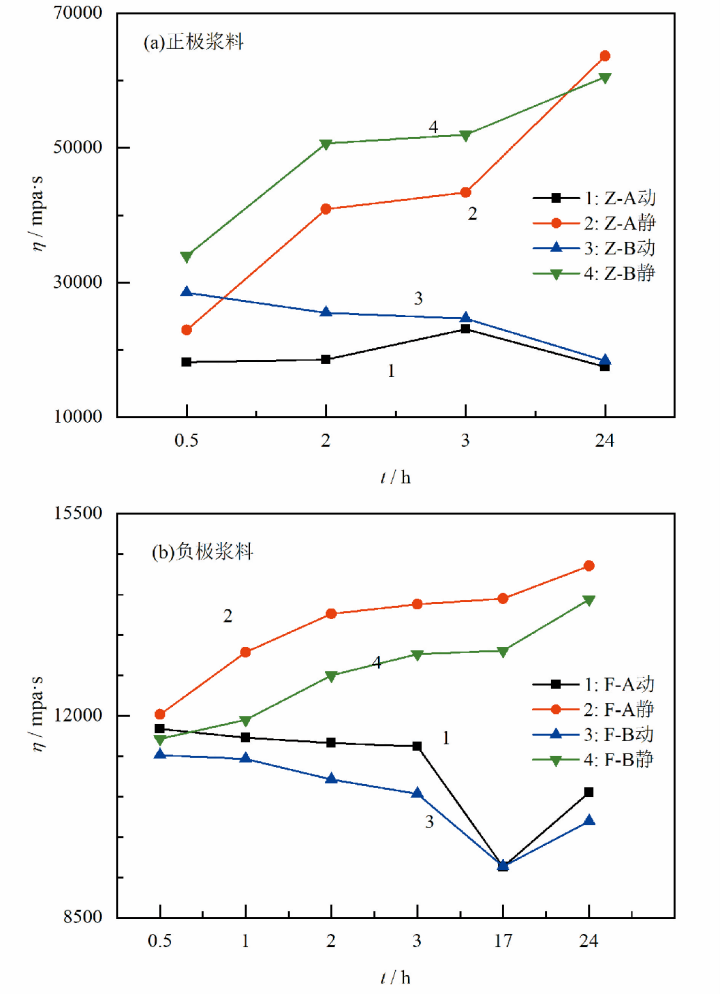

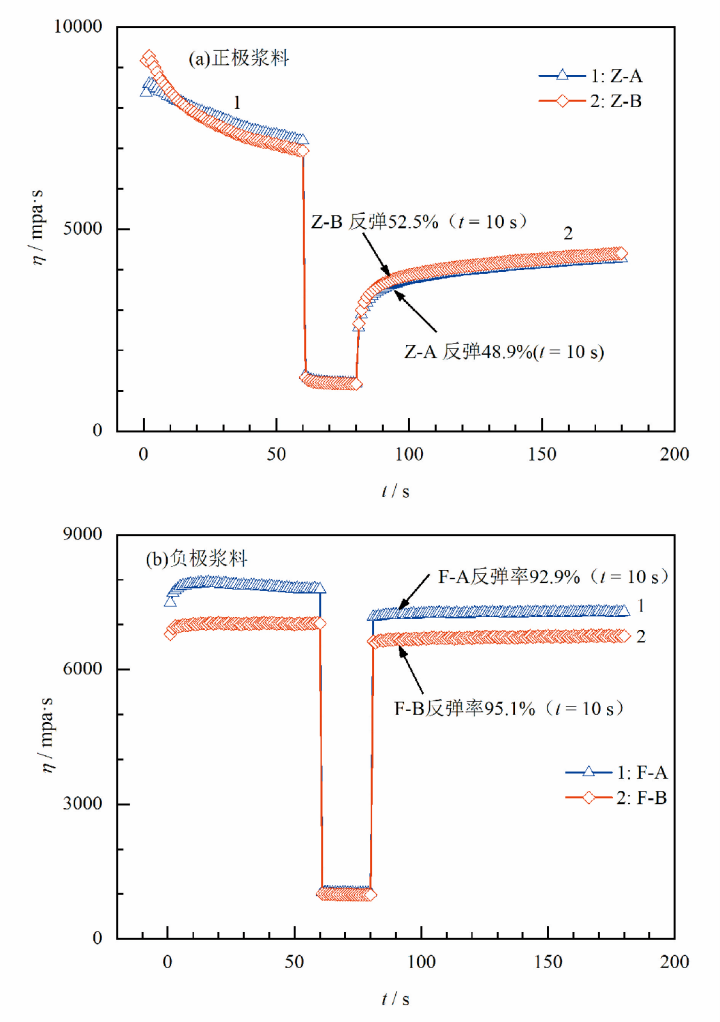

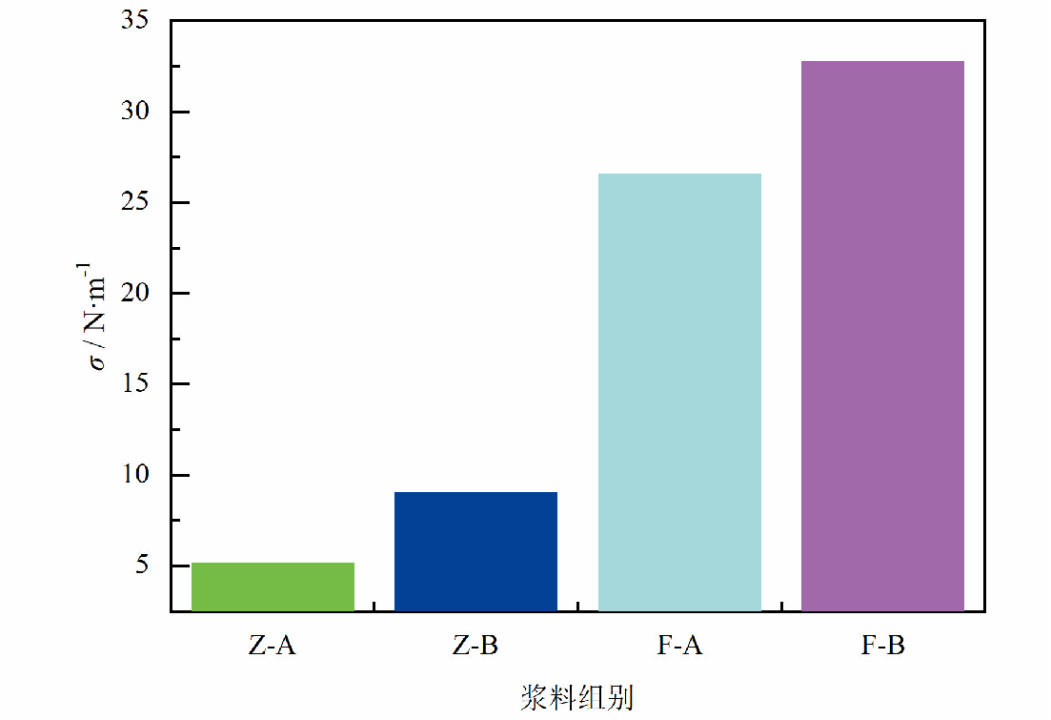

摘要:近两年,出现了有别于传统搅拌机及双螺杆的锂离子电池高效循环制浆系统(见图1)。各种粉体经过计量进入粉料仓,液体通过计量进入循环罐,进行初步混合。启动转子泵,液体进入合浆机,进料2 min后,管道上部落料管道形成一定微小负压。粉料通过转子阀,经螺杆输送,进入合浆机,经过弥散、雾化,与液体组分进行润湿、分散,进入循环罐。经过多次循环分散后,产出成品浆料。为了解高效匀浆系统适合的工艺流程,采用干法和湿法工艺,分别制备固含量为62%的磷酸铁锂浆料和固含量为52%的石墨浆料。相比较于干法工艺,采用湿法工艺能解决在短时间胶粉难以溶解和各组份混合不均匀的问题。湿法工艺的正极浆料Z-B动态黏度比干法Z-A的28 500 mPa·s低10 300 mPa·s(见图2)。正极浆料采用湿法工艺,高速剪切后10 s的反弹率比干法Z-A的48.9%高3.6%(见图3),细度比干法更小,四探针电阻率比干法Z-A的5.587 8 Ω·cm低0.041 0 Ω·cm,极片黏结力比干法Z-A高出76.46%(见图4)。负极浆料采用湿法工艺,高速剪切后10 s的反弹率比干法F-A的92.9%高2.2%(见图3),触变环的面积比干法F-A的83.552 Pa/(s·cm3)低45.5%(见图5)。SEM分析表明,干法浆料比湿法浆料团聚严重,进一步说明无论是正极还是负极,采用湿法制浆工艺,即胶粉提前溶解,更加适合高效循环制浆系统。

High efficiency circular pulping process of Li-ion battery

YUAN Tianming∗, SUN Xiaohui, RUAN Chao, LI Jingkang

(Processing Technology Section, Hangzhou Narada Motive Power Science & Technology Co., Ltd., Hangzhou, Zhejiang 311103, China)

Abstract: In the past two years, a high-efficiency circulating slurry system for Li-ion battery has emerged, which is different from traditional mixers and twin screws pulping technology (as shown in Fig.1). Various powders are measured and enter the powder silo for mixing. The liquid is metered and enters the circulation tank for initial mixing. Start the rotor pump, and the liquid enters the mixer. After 2 min of feeding, a certain small anode pressure is formed in the upper part of the discharge pipeline. The powder is conveyed through a rotary valve, screw conveyor, and enters the mixing machine. After dispersion and atomization, it is wetted and dispersed with liquid components before entering the circulation tank. After multiple cycles of dispersion, the finished slurry is produced. To understand the suitable process flow for efficient homogenization systems. Lithium iron phosphate slurry with a solid content of 62% and graphite slurry with a solid content of 52% are prepared respectively by using dry and wet processes. Compared to the dry process, using the wet process can solve the problem of rubber powder is difficult to dissolve and the components are mixed unevenly in a short time. The viscosity of the cathode slurry in the wet process Z-B is 10 300 mPa·s lower than that of the dry method Z-A at 28 500 mPa·s (as shown in Fig.2). Cathode slurry prepared with wet process, the rebound rate after 10 s of high-speed shear is 3.6% higher than that of the dry method Z-A at 48.9% (as shown in Fig.3), and the fineness is smaller than that of the dry method. The internal resistance of the four probes is 0.041 0 Ω·cm lower than that of the dry method Z-A at 5.587 8 Ω·cm, and the electrode bonding force is 76.46% higher than that of the dry method Z-A (as shown in Fig.4). Anode slurry prepared with wet process, the rebound rate of the anode slurry after high-speed shear for 10 s is 2.2% higher than that of the dry method F-A of 92.9% (as shown in Fig.3). The area of the thixotropic ring is 45.5% lower than that of the dry method of 83.552 Pa/(s·cm3) (as shown in Fig.5). According to SEM testing analysis, the agglomeration of dry process slurry is more severe than that of wet process slurry, further revealing that wet process slurry is more suitable for efficient circulating pulping systems, regardless of the cathode or anode.

图1 高效制浆系统示意图

Fig.1 Schematic diagram of efficient pulping system

图2 浆料的动态和静置黏度

Fig.2 Dynamic and static viscosities of slurries

图3 浆料的高速剪切反弹率

Fig.3 Rebound rates of slurries after high-speed shearing

图4 浆料的触变性

Fig.4 Thixotropies of slurries

图5 极片的平均剥离强度

Fig.5 The peel strength of polar plates

引用格式

袁天明,孙晓辉,阮超,等. 锂离子电池浆料高效循环制备工艺[J]. 电池,2024,54(2):222-226.

YUAN T M,SUN X H,RUAN C,et al. High efficiency circular pulping process of Li-ion battery[J] . Dianchi( Battery Bimonthly),2024,54(2):222-226.(点此下载文章全文)

姚良少

( 郁南虎头电源科技有限公司,广东 云浮 527199 )

摘要:利用钢壳是磁性材料的特性,将强力磁铁应用于高速自动化碱性锌锰电池生产线,以解决钢壳在运输过程中变形的问题。借鉴高速自动化LR6电池生产线集流体插入机采用强力磁铁吸取集流体的方式,将LR12电池集流体插入机由真空抓取集流体改造为强力磁铁吸取集流体的方式,并对拾取杆前端吸头材料进行优化,增加预收口功能,加装弹性装置解决滑杆吸头吸附集流体难以脱离的问题。以LR12电池集流体插入机改造为例,比较真空吸取集流体和强力磁铁吸取集流体这两种方式的缺点。实践证明,使用强力磁铁吸取集流体,不仅提高了5%的设备运转率和2%的产品合格率,而且节省了维修费用。

Application of strong magnets in alkaline Zn-MnO2 battery production line

YAO Liangshao

(Yunan Tiger Head Power Supply Science and Technology Co., Ltd., Yunfu, Guangdong 527199, China)

Abstract: The application of strong magnets in high-speed automated alkaline Zn-MnO2 battery production lines can solve the problem of deformation of steel shells during transportation, taking the characteristic that steel shell is a magnetic material. The LR12 battery fluid collection insertion machine, which originally used vacuum suction fluid collection, has been transformed into a method where the current collectors are attracted using strong magnets, like the high-speed automated LR6 battery production line. Additionally, the material of the suction head at the front end of the pick-up rod has been optimized, with the addition of a pre-receiving function and the installation of an elastic device to solve the issue of current collectors being difficult to detach from the suction head on the sliding rod. Taking the renovation of the LR12 battery fluid collection insertion machine as an example, the shortcomings of vacuum suction fluid collection and strong magnet suction fluid collection are compared. The practice has proven that the use of strong magnets to absorb fluid not only improves equipment operation rate by 5% and product qualification rate by 2% but also saves maintenance costs.

图1 改造后的LR12电池集流体插入机

Fig.1 LR12 battery collector insertion machine after renovation

引用格式

姚良少. 强力磁铁在碱性锌锰电池生产线上的应用[J]. 电池,2024,54(2):227-229.

YAO L S. Application of strong magnets in alkaline Zn-MnO2 battery production line[J] . Dianchi(Battery Bimonthly),2024,54(2):227-229.(点此下载文章全文)

陈道林,陈崔龙,张曼曼∗,周 俊

(合肥通用机械研究院有限公司,安徽 合肥 230088)

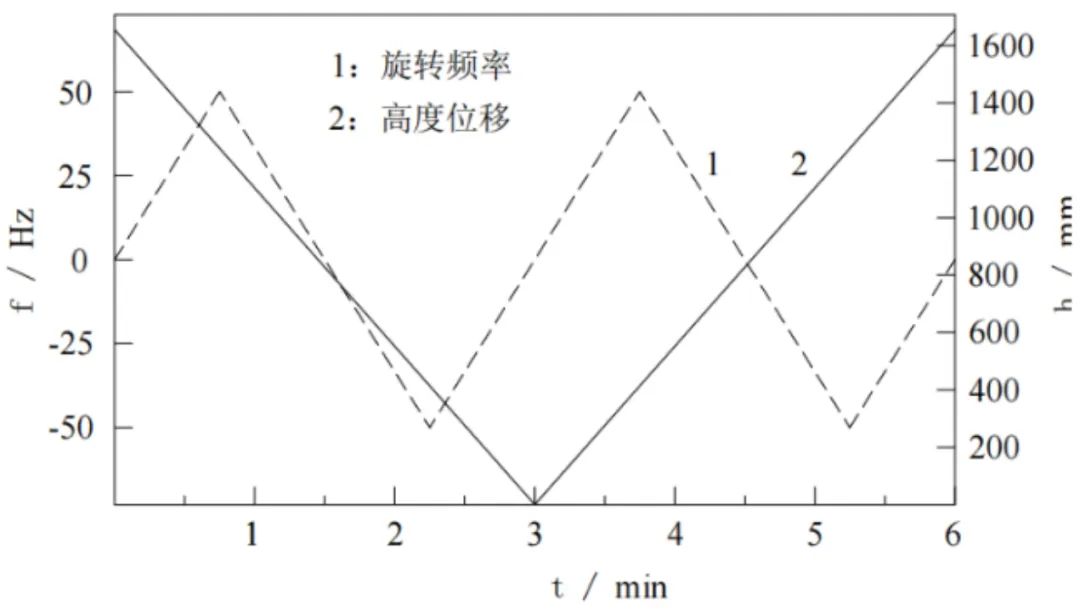

摘要:为满足三元材料前驱体生产过程对洗涤日趋严格的要求,对研制的多功能一体机洗涤方式和机理进行分析,得出多维洗涤是解决前驱体杂质含量高、洗涤废水量大的可靠工程方法。通过将洗涤过程中的正反向旋转、转速、升降等动作优化组合,且不同动作与相应时间进行匹配,通过专门设计的程序对变频系统和液压系统进行控制,实现多维运动场,并与前驱体特性有机融合,实现多维洗涤模式,具体动作为:搅拌桨叶刮刀先正向旋转,升速到最高50 Hz时,降速至0 Hz,再反向旋转升速到50 Hz,然后降速至0 Hz,再正向旋转升速到50 Hz,依次变化;同时,搅拌桨叶刮刀从最高位置下降至最低位置后,又上升至最高位,搅拌桨叶刮刀在洗涤搅拌时随着时间的变化,实现空间位置上下、转速方向以及快慢的不断改变。具体工作参数示例见图1。洗涤后的前驱体,钠(Na)的质量分数为0.015%、硫(S)的质量分数为0.14%、磁性异物的质量分数不超过5.0×10-6%,均优于国家标准,并减少了废水排放。

Design of multi-dimensional washing system for precursor of ternary cathode material

CHEN Daolin, CHEN Cuilong, ZHANG Manman∗, ZHOU Jun

(Hefei General Machinery Research Institute, Hefei, Anhui 230088, China)

Abstract: To meet the increasingly strict requirements for washing in the production process of ternary material precursors, multi-dimensional washing is a reliable engineering method for solving the high impurity content and large washing wastewater of precursors through the analysis of the washing method and mechanism of the developed multifunctional all-in-one machine. By optimizing the combination of forward and reverse rotation, speed, and lifting actions during the washing process, and matching different actions with corresponding times, a specially designed program is used to control the frequency conversion system and hydraulic system to achieve a multi-dimensional motion field, which is organically integrated with the characteristics of the precursor to achieve a multi-dimensional washing mode. The specific actions are as follows: the stirring blade scraper first rotates in the forward direction, and when the speed reaches the maximum 50 Hz, it slows down to 0 Hz, then rotates in the reverse direction to increase the speed to 50 Hz, then slows down to 0 Hz, and then rotates in the forward direction to increase the speed to 50 Hz, and changes in sequence; At the same time, the stirring blade scraper descends from the highest position to the lowest position and then rises to the highest position. The stirring blade scraper achieves continuous changes in spatial position, speed direction, and speed over time during washing and stirring. An example of specific working parameters is shown in the Fig.1. After the precursor is washed, the mass fraction of sodium (Na) is 0.015%, the mass fraction of sulfur(S) is 0.140% and the mass fraction of magnetic foreign matter is no more than 5.0×10-6%, which is better than the national standards and reduces wastewater discharge.

图1 多维洗涤工作参数示例

Fig.1 Example of parameters of multi-dimensional washing working

引用格式

陈道林,陈崔龙,张曼曼,等. 三元正极材料前驱体多维洗涤系统的设计[J]. 电池,2024,54(2):230-234.

CHEN D L, CHEN C L, ZHANG M M, et al. Design of multi-dimensional washing system for precursor of ternary cathode material[J]. Dianchi(Battery Bimonthly),2024,54(2):230-234.(点此下载文章全文)

吴圣明∗,吕 亮,周 怡,郭营军

(湖州昆仑亿恩科电池材料有限公司,浙江 湖州 313000)

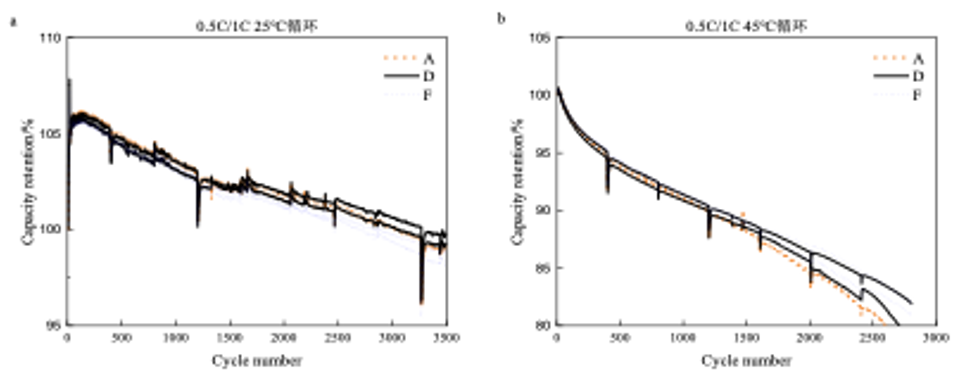

摘要:添加双氟磺酰亚胺锂(LiFSI)可改善电解液的导电性和稳定性,但有腐蚀铝箔的风险。通过调整电解液中LiFSI和六氟磷锂(LiPF6)的比例,研究LiFSI添加量对铝箔腐蚀和电池性能的影响。循环伏安测试结果表明,随着LiFSI添加量的增加,电解液对铝箔腐蚀效果增强,当LiFSI质量分数为12.5%时,铝箔在25 ℃、45 ℃下分别于3.5 V左右、3.8 V左右开始发生腐蚀。没有LiPF6在铝箔表面形成AlF3的保护,铝箔容易发生腐蚀。电池循环性能测试结果表明,当LiFSI质量分数为6.0%、LiPF6质量分数为6.5%时,电池在2.50~3.65 V以0.5 C充电1.0 C放电,25 ℃下循环3 500次的容量保持率为99.5%。

Effect of bis(fluorosulfonyl)imide addition on the performance of electrolyte

WU Shengming∗, LYU Liang, ZHOU Yi, GUO Yingjun

(Huzhou Kunlun Enchem Battery Material Co., Ltd., Huzhou, Zhejiang 313000, China)

Abstract: The addition of bis(fluorosulfonyl)imide(LiFSI) can improve the conductivity and stability of electrolytes, but will lead to corrosion risk of aluminum foil. The effect of LiFSI content on the corrosion of aluminum foil and the battery performance is studied by adjusting the ratio of LiFSI and lithium hexafluorophosphate (LiPF6) in the electrolyte. The CV test results show that with the increase of LiFSI content, the corrosion effect of the electrolyte on the aluminum foil is enhanced. When the LiFSI mass fraction is 12.5%, the aluminum foil begins to corrode at about 3.5 V at 25 ℃ and begins to corrode at about 3.8 V at 45 ℃. The aluminum foil is prone to corrosion without the protection of AlF3 formed by LiPF6 on the surface of the aluminum foil. The cycle performance test results show that when the mass fraction of LiFSI and LiPF6 is 6.0% and 6.5% respectively, the battery is charged at 0.5 C and discharged at 1.0 C in 2.50-3.65 V, the capacity retention rate is 99.5% after 3 500 cycles at 25 ℃.

(a)25 ℃循环;(b)45 ℃循环

图1 电解液A、D、F制备电池的循环性能

Fig.1 Cycle performance of battery with A, D, F electrolytes

引用格式

吴圣明,吕亮,周怡,等. 双氟磺酰亚胺锂添加量对电解液性能的影响[J]. 电池,2024,54(2):235-238.

WU S M,LYU L,ZHOU Y,et al. Effect of bis(fluorosulfonyl)imide addition on the performance of electrolyte[J]. Dianchi(Battery Bimonthly),2024,54(2):235-238.(点此下载文章全文)

讨论会

赵丽香,王晓冬∗,刘冉冉,何鹏林

(中国电子技术标准化研究院,北京 100176)

摘要:随着锂离子储能电池装机量不断增加,因电池诱发的储能事故时有发生,为更好地开展储能用锂离子电池标准制修订工作,促进储能用锂离子电池产业高质量发展,调研了锂离子电池储能产业发展概况,分析了国内外储能用锂离子电池安全和储能系统相关标准化现状及标准的适用范围和技术内容,并提出了当前存在的问题。目前,国际电工委员会(IEC)、美国保险商实验室(UL)和国内相关标准化机构已制定基础准入标准,但是还存在标准考核不全面、缺乏适用性及缺少安全等级评价标准等方面的问题。提出了后续标准制修订过程中应以有效评估储能用锂离子电池的安全性为目的,加强对锂离子电池全生命周期安全性的评估,并注重锂离子电池多方面的考核,充分发挥标准的引领作用,以此助推储能产业高质量发展。

Status of safety evaluation standards for Li-ion battery for energy storage

ZHAO Lixiang, WANG Xiaodong∗, LIU Ranran, HE Penglin

(China Electronics Standardization Institutes, Beijing 100176, China)

Abstract: With the number of installed energy storage Li-ion batteries increasing, energy storage accidents caused by batteries occur frequently. To carry out the revision of Li-ion battery standards for energy storage, and promote the high-quality development of the Li-ion battery industry for energy storage, the general situation of industrial development is investigated, the safety standardization status of Li-ion batteries for energy storage at home and abroad is analyzed. At present, the International Electrotechnical Commission (IEC), Underwriters Laboratories (UL), and relevant domestic standardization bodies have developed basic access standards. However, some standards have the problems of incomplete assessment and lack of applicability. In addition, there is a lack of relevant standards for safety grade evaluation. To promote the high-quality development of the industry, it is suggested that the safety of Li-ion batteries for energy storage should be evaluated effectively in the process of standard revision.

引用格式

赵丽香,王晓冬,刘冉冉,等. 储能用锂离子电池安全评价标准现状[J]. 电池,2024,54(2):239-243.

ZHAO L X,WANG X D,LIU R R,et al. Status of safety evaluation standards for Li-ion battery for energy storage[J] .Dianchi(Battery Bimonthly),2024,54(2):239-243.(点此下载文章全文)

往期回顾

01

02

03

微信编辑 汤翊 责编 复审 刘冰 终审 李胜

点击蓝字

关注我们

扫|码|关|注

欢迎订阅《电池》杂志

了解更多精彩内容

本刊未委托任何第三方机构或个人代为收费或组稿,作者朋友们请投稿至唯一指定邮箱:dianchi@batterypub.com

-1971年创刊-欢迎转载传播-

版权声明

本文仅作者转发或者创作,不代表旺旺头条立场。

如有侵权请联系站长删除

- 1 亲爱的妳 | 女教师的「智性衣橱」 ...

- 2 NEW IN | 秋风起,印花依旧迷人 ...

- 3 本周活动指南,暑期观影夏令营,萌宠运动会...更多精彩尽在漳州台商万达! ...

- 4 ETF投资知识5 | 手把手教你ETF如何买卖 ETF怎么买?ETF虽然也是基金,但是他的交易方式却等同于股票。因此,想要买卖ETF,首先要有个可以买卖股票的股票账户,还未开通股票账户的投资者可参阅《民生证券开户指南》。然后,投资者们只需要在自己的“民生财富汇App”中输入对应的ETF代...

- 5 根网科技祝您中秋快乐——月满人圆 喜乐安康! 皓月当空,心海澄明君之所想,吾志所向...

- 6 党的二十届三中全会公报一图读懂 来源:新华社免责声明:以上内容基于本公司认为可靠的已公开信息整理形成,民生证券力求但不保证内容的准确性和完整性,不保证已做最新变更。以上内容仅供参考,不构成民生证券做出的投资建议、收益承诺或对任何观点的认可。投资者应自主进行投资决策,民生证...

- 7 四大行,历史新高 预计阅读时间 | 3 分钟正文丨 1053 字今天,银行股持续走高。工商银行、农业银行、中国银行、建设银行均创历史新高,邮储银行再创阶段新高。今年以来,银行股整体表现强势,领涨大盘。据东方财富Choice数据,年初至今,农业银行...

- 8 1F UNDER ARMOUR | 运动就进阶,精选商品低至3折起 ...

- 9 官宣!苹果发布会:9月10日凌晨1点 入手 iPhone 15,现在正是好时机!指定型号立减 1300 元!更多精彩资讯...

- 10 端午休市安排(附国债逆回购攻略) 国债逆回购小贴士1️⃣ 国债逆回购是什么?国债逆回购可以理解为一种短期借贷。通俗地说,你把钱借给别人,获得固定利息;而别人用国债作抵押,到期还本付息。国债逆回购是由交易所交易并进行监管,不会出现到期资金不能归还的情况。历史经验显示,每逢季末...

- 正义判决!宜生无忧声明:前员工敲诈勒索终获十年刑责 6天前

- 春天有XIN事 | 春天来了,这群物业人有什么心事? 6天前

- 美团发布2024年Q4及全年财报:一起更好,Better Together 6天前

- 宜生动态丨宜生无忧受邀参加沈阳残疾人就业洽谈会 6天前

- 国际专家亲诊 | 3月14-15日,英国爱丁堡大学欧山林博士亲诊,国际顶尖水准触手可及,缺牙“即刻重生” 6天前

- 低价陷阱受害者控诉惨痛经历:隐形加价,维权无门 6天前

- 黄陈宏博士转任用友网络董事 6天前

- 元气森林创造营2044:年轻人、创新、热爱、试试 6天前

- 我们邀请您一起共创好产品 6天前

- 打造铁路信号智能运维“超级医生”——“和行”轨道交通大模型让运维更高效 6天前

旺旺头条

旺旺头条

发表评论:

◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。