在全球新能源浪潮的推动下,涂布技术成为提升电池性能的关键。面对日益增长的国际市场对高性能电池的渴求,高效、精密、智能的涂布解决方案成为全球竞逐的焦点,驱动着智能制造的不断进步与融合。

在此形势下,利元亨作为全球智能装备制造的优秀企业,凭借其技术创新方面的深厚积淀,针对不同的电池生产应用需求,将多年累积的精湛工艺转化为实际成果,推出首款1800mm高速宽幅涂布机,引领产业升级,应对全球挑战。

利元亨高速宽幅涂布机,融汇集放卷、纠偏、张力控制、浆料处理、涂布、烘干、牵引、收卷等核心工艺于一身,构筑了一体化、高效能的生产链。该设备通过精细调控,实现浆料的完美均匀分布,确保基材上的尺寸、重量精准达标,为电池制造的后续步骤奠定了坚实基底。配备1800mm超宽涂布辊面,匹配超宽基材,作业效率与覆盖范围双提升。运行速度峰值可达150m/min,大幅度缩短生产周期,效率显著提升。

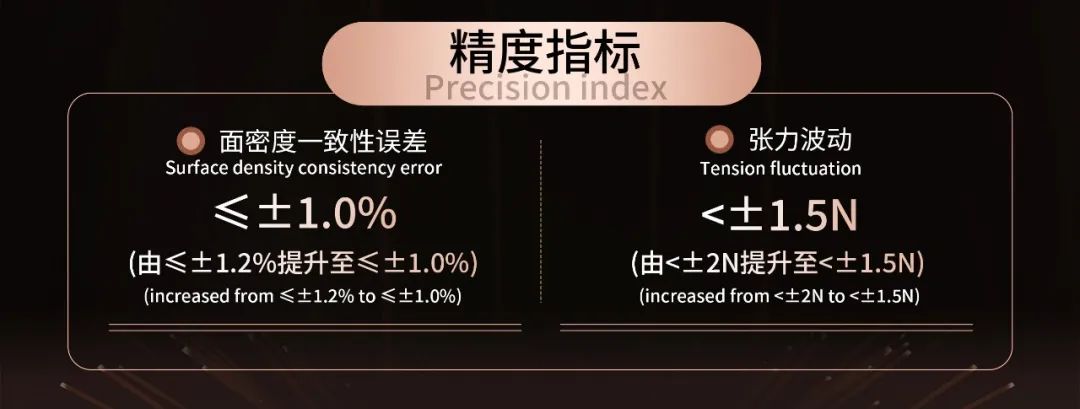

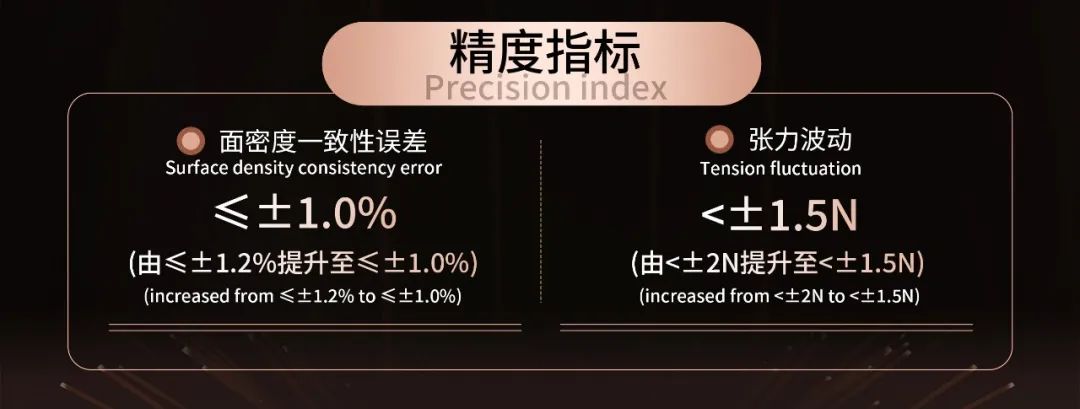

涂布机凭借垫片规格以及涂布阀的灵活组合,实现涂布工艺的多元适应性。纠偏与张力控制系统分别以±0.1mm与±1.5N的精度运行,确保涂布留白尺寸的精准无瑕。精准把控面密度误差与横纵双向的高精度指标,模头唇口维持2μm的直线精度,力保涂布层均匀一致。涂布尺寸精度误差≤±0.3mm,每一细节都体现了对工艺精准度的极致追求与把控。

涂布机烘箱内置智能温控核心,其配备的高灵敏监控系统与多类型传感器,旨在高效节能与均匀干燥极片,提升品质。实时分析并智能调节风机、风阀及温控参数,确保极片运行状态及干燥效果的均匀。针对多元生产需求,系统即刻云对接,无缝切换预设参数,加速生产节拍。配合远红外技术,提升干燥品质及效率。创新融入AGV自动化物流,显著降低人工介入与停机次数,提升生产线的连续生产力,同时节省人力超过30%,在确保效率最大化的同时,实现了成本控制的最优平衡。

在新能源产业快速演进的当下,利元亨将持续以创新为驱动,为全球电池产业的绿色、高效发展贡献更多“中国智慧”。于此同时,利元亨还将加强与合作伙伴的合作,共同推动涂布设备的创新和发展,为行业的繁荣做出更多的贡献,引领电池制造进入一个全新的智能高效时代。

Coming at dawn, wide width leads the way- Lyric first 1800mm high-speed wide coating machine

Driven by the global wave of new energy, coating technology has become the key to improving battery performance. Faced with the growing international market demand for high-performance batteries, efficient, precise and intelligent coating solutions have become the focus of global competition, driving the continuous progress and integration of intelligent manufacturing.

Under this situation, as an outstanding global intelligent equipment manufacturing company, Lyric, relying on its profound accumulation in technological innovation, has transformed years of accumulated exquisite craftsmanship into practical results in response to different battery production and application needs, and launched the first 1800mm high-speed wide-width coating machine, leading the industry upgrade and responding to global challenges.

Innovative design, wide width remodeling

Lyric high-speed wide-width coater integrates core processes such as unwinding, deviation correction, tension control, stock handling, coating, drying, traction, winding, etc., to build an integrated, high-efficiency production chain. The device achieves perfect and uniform distribution of the slurry through fine regulation, ensuring that the size and weight on the substrate are accurately up to standard, and laying a solid foundation for the subsequent steps of battery manufacturing. Equipped with 1800mm ultra-wide coating roller surface, matching ultra-wide substrate, work efficiency and coverage double increase. The peak running speed can reach 150m/min, which greatly reduces the production cycle and significantly improves the efficiency.

Precision control, excellent quality

The coater achieves multiple adaptability of the coating process through the flexible combination of gasket specifications and coating valves. The correction and tension control systems operate with accuracy of ±0.1mm and ±1.5N, respectively, to ensure accurate and flawless coating white space. Accurately control the density error of the control surface and the high precision index of the horizontal and vertical direction, maintain the linear accuracy of 2μm at the lip of the die head, and ensure the uniform coating layer. Coating size accuracy error ≤±0.3MM, every detail reflects the ultimate pursuit and control of process accuracy.

Intelligent upgrade, efficiency jump

The coating machine oven has a built-in intelligent temperature control core. It is equipped with a highly sensitive monitoring system and multiple types of sensors, aiming to save energy efficiently, dry the electrode uniformly, and improve quality. Real-time analysis and intelligent adjustment of fan, air valve and temperature control parameters to ensure electrode operating status and drying effect. In response to diverse production needs, the system instantly connects to the cloud, seamlessly switches preset parameters, and accelerates production pace. Combined with far-infrared technology, it improves drying quality and efficiency. The innovative integration of AGVautomated logistics significantly reduces the number of manual interventions and shutdowns, improves the continuous productivity of the production line, and saves more than 30% of manpower. It achieves the optimal balance of cost control while ensuring maximum efficiency.

The current new energy industry is in the process of rapid development and change. Lyric will continue to be driven by innovation and contribute more "Chinese wisdom" to the green and efficient development of the global battery industry. At the same time, Lyric will also strengthen cooperation with partners to jointly promote the innovation and development of coating equipment, make more contributions to the prosperity of the industry, and lead battery manufacturing into a new era of intelligence and efficiency.

旺旺头条

旺旺头条

发表评论:

◎欢迎参与讨论,请在这里发表您的看法、交流您的观点。